Supply Network Planning

Challenges

Despite many companies having legacy planning systems, the sales and operations planning (S&OP) process is still primarily manual and based on spreadsheets. These planning solutions often lack optimization capabilities and instead focus more on the current process and constraints, rather than finding alternative solutions that can result in direct cost savings.

The fast-changing world means that the S&OP process needs to be constantly updated. Legacy planning systems and processes, however, are not able to quickly update plans or generate alternative scenarios. These changes can result in the spending of millions or even tens of millions of dollars every week.

Sophus Solution

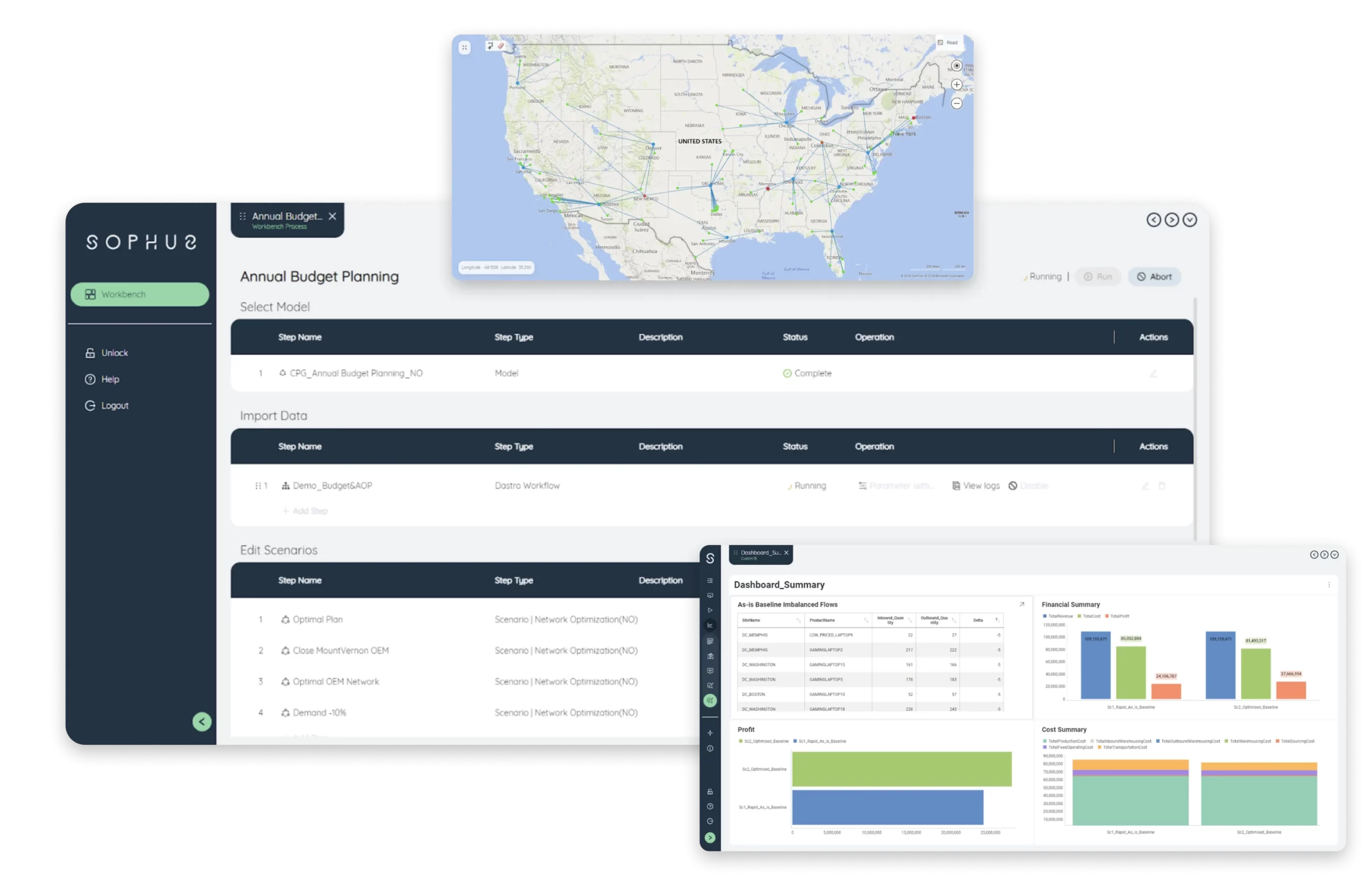

SophusX provides a single integrated and optimized plan for all S&OP processes, incorporating real-time what-if scenario building and evaluation capabilities.

The platform optimizes the plan to dictate what to produce, how much to produce, when to produce, where to produce, if pre-build inventory is needed, what model of transportation to use and how much raw materials to source, if extra shifts are needed, and if any/how much to outsource.

Benefits

Variable Production Cost reduction of up to

6-8%

Capacity Utilization improvement of up to

35-40%

Logistics cost reduction of up to

8-10%

By using SophusX, companies can have a more streamlined and efficient S&OP process, resulting in cost savings and improved utilization of resources.

Request a demo