Inventory planning no longer happens at a single location. In modern supply chains, decisions made at plants, central DCs, and regional DCs are deeply connected. Multi-Echelon Inventory Optimization (MEIO) addresses this challenge by inventory optimization and replenishment across the entire network at once.

Gartner notes that increasingly global and complex supply chains are driving the need for multi-echelon inventory optimization. According to Gartner, MEIO helps CSCOs reduce inventory while maintaining target service levels by balancing supply and demand across multiple stocking locations, rather than optimizing each node in isolation. This approach also enables more effective supply chain segmentation and network-wide decision-making.

MEIO helps answer questions traditional models cannot: What happens to service and cost if we shift inventory from regional DCs to a central DC? Should we hold more raw materials or more finished goods? Which intermediate item is creating the biggest bottleneck across the network?

This guide explains what MEIO is, why inventory efficiency matters today, and how MEIO supports better, network-wide inventory decisions.

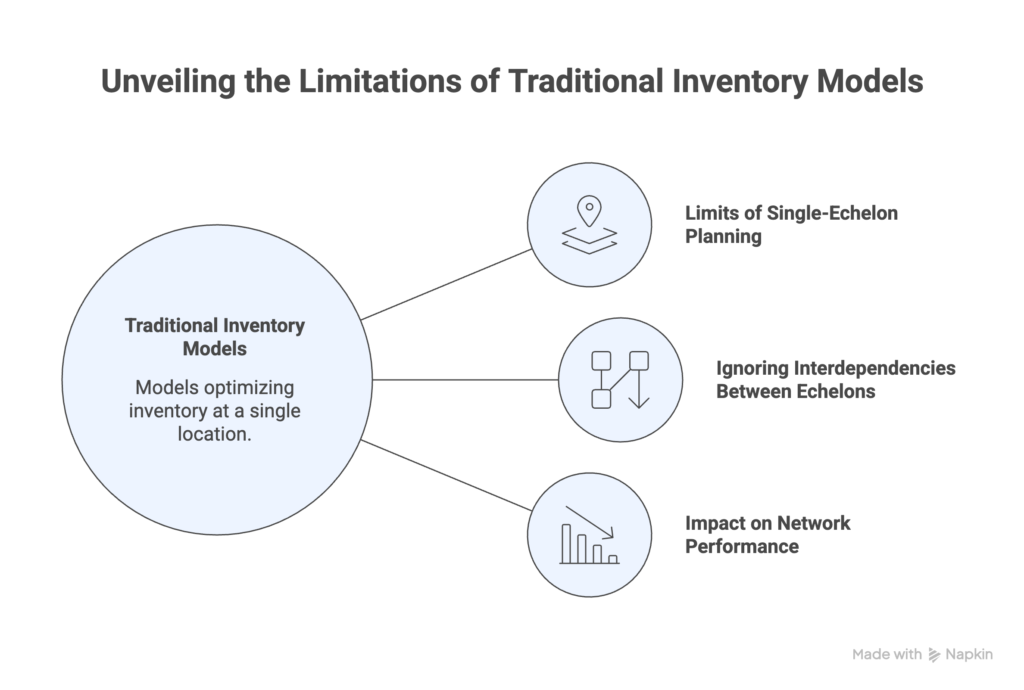

Why Traditional Inventory Models Fall Short

Traditional inventory approaches were designed for simpler, more predictable supply chains. As networks expand across plants, central DCs, regional DCs, and markets, these models fail to reflect how inventory decisions truly behave at scale.

Limitations of Single-Echelon Inventory Systems

Single-echelon models focus on optimizing inventory at one location at a time, using local demand, lead time, and service targets. While this may work for standalone warehouses, it breaks down in multi-tier networks. These models cannot evaluate trade-offs between upstream and downstream stocking, often resulting in duplicated safety stock and inflated inventory and stockouts at the same time across the network.

Inability to Account for Interdependencies Between Echelons

In a real supply chain, inventory decisions are connected. Increasing safety stock at a regional DC may reduce risk locally but increase pressure on central DCs or plants. Single-echelon models ignore these cause-and-effect relationships, making it impossible to understand how changes in one echelon shift cost, risk, and service elsewhere.

Consequences of Poor Inventory Decisions on Network Performance

When interdependencies are ignored, inventory grows without improving service levels. Companies face higher working capital, frequent expediting, longer lead times, and unstable fulfillment performance. Over time, planners spend more time firefighting than optimizing, while leadership struggles to explain why inventory keeps rising but customer service does not improve.

Core Principles of Multi-Echelon Inventory Optimization (MEIO)

At its core, Multi-Echelon Inventory Optimization (MEIO) is about balancing uncertainty across the entire supply network. Instead of buffering demand variability at every location, MEIO decides where uncertainty should be absorbed to deliver the best overall service at the lowest total cost.

Demand Variability, Lead Times, and Service Levels

Demand variability increases as you move closer to the customer, while lead times typically grow as you move upstream. MEIO explicitly models this behavior and determines how much inventory is needed at each echelon to meet target service levels without overstocking the network.

Understanding Interdependencies Between Echelons

In a multi-echelon framework, inventory at one level protects others. Safety stock held at a central DC can reduce the need for buffers at regional DCs, while long production lead times may justify holding inventory earlier in the chain. MEIO captures these interdependencies, ensuring demand variability, lead times, and service levels are balanced across the network rather than optimized in isolation.

Benefits of Implementing Multi-Echelon Inventory Optimization (MEIO)

MEIO Multi-Echelon Inventory Optimization turns inventory planning from static rule-setting into a dynamic, network-wide decision process. Instead of reacting to shortages or excess stock, organizations gain the ability to proactively balance cost, risk, and service across the entire supply chain.

Optimized Safety Stock Across All Echelons

With Sophus, safety stock is not calculated in isolation. Its decision intelligence layer dynamically determines how much to stock, where to stock, and what to stock across plants, DCs, and downstream nodes. By modeling constraints and interdependencies across the multi-echelon network, Sophus reduces excess inventory while maintaining reliable service levels where they matter most.

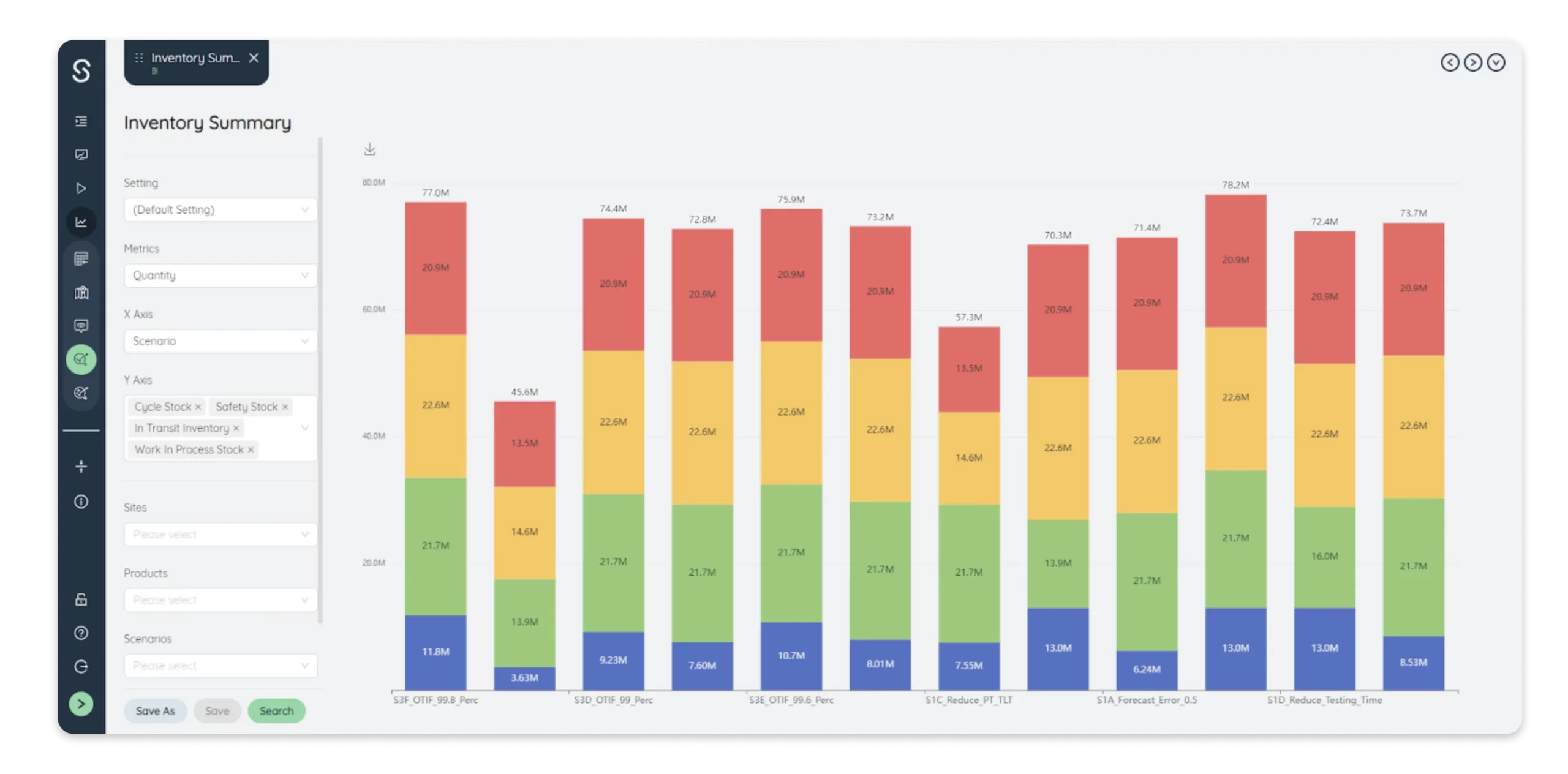

Scenario Simulation and Rapid Baselining

Sophus allows planners to test “what-if” scenarios such as supplier delays, demand spikes, or network changes. Inventory strategies can be recalibrated quickly, helping teams understand trade-offs and establish robust baselines without long planning cycles.

Lifecycle-Aware Inventory Planning

Inventory needs change over a product’s lifecycle. Sophus adapts MEIO models to launches, promotions, maturity, and end-of-life phases, ensuring inventory stays aligned with real business dynamics rather than fixed assumptions.

Challenges and Common Pitfalls in MEIO Inventory

While MEIO delivers strong results, it is not a plug-and-play solution. Success depends on correctly modeling the network and aligning teams around shared objectives.

Identifying and Quantifying Interdependency Factors

One of the biggest challenges in MEIO is accurately capturing how echelons influence each other. Demand variability, lead times, service targets, and replenishment rules interact across plants, DCs, and downstream nodes. If these interdependencies are poorly defined or oversimplified, MEIO outputs can look precise but lead to wrong stocking decisions.

Implementation and System Integration Complexity

MEIO requires clean data, consistent master data, and integration with ERP, planning, and execution systems. Many organizations struggle with fragmented data sources or legacy tools, which slows adoption and limits model accuracy.

Misalignment of Goals Across Echelons

Different echelons often optimize for conflicting goals. Plants focus on efficiency, DCs focus on availability, and sales teams push for high service levels. Without alignment, MEIO recommendations face resistance and fail to deliver network-wide benefits.

MEIO in Practice: Use Cases Across Industries

Real-world MEIO success depends on understanding the full network and making inventory decisions in context, not in isolation. The following case studies show how MEIO works when combined with strong network design and decision intelligence.

Food Distribution: Uncovering Hidden Inventory Imbalances

In a large food distribution network, Sophus revealed $20M in hidden savings by analyzing how inventory was positioned across multiple DCs. MEIO exposed where safety stock was duplicated and where service buffers were misplaced. By rebalancing inventory across echelons, the company reduced excess stock while maintaining service levels in high-demand regions.

Network Design as the Foundation for MEIO

In a European supply chain transformation, Sophus showed how network design acts as the backbone of MEIO. By redesigning the network first, planners could then apply MEIO to optimize inventory across plants, hubs, and markets. The result was lower total inventory, faster response times, and more stable service across regions.

Steps to Implement MEIO Successfully

Implementing MEIO is not just a modeling exercise. It requires the right foundation, the right people, and an ongoing commitment to improve decisions as conditions change.

Assess Current Inventory Practices and Identify Gaps

Start by reviewing how inventory is planned today. Identify where single-echelon logic is used, where safety stock is duplicated, and where service targets are unclear or inconsistent. These gaps often signal where MEIO can deliver the biggest impact.

Build a Cross-Functional MEIO Team

MEIO touches multiple functions, including supply chain planning, manufacturing, logistics, sales, and finance. A cross-functional team ensures that service goals, cost targets, and operational constraints are aligned before MEIO recommendations are applied.

Use Technology for Data Analysis and Optimization

MEIO requires tools that can model demand variability, lead times, constraints, and network interdependencies at scale. Modern optimization and decision intelligence platforms make it possible to run scenarios, test trade-offs, and update plans quickly.

Continuously Monitor and Adjust MEIO Strategies

Supply chains change constantly. Demand shifts, suppliers evolve, and networks expand. MEIO must be monitored and recalibrated regularly to remain effective, ensuring inventory decisions stay aligned with real-world conditions and business priorities.

Ready for MEIO?

Modern supply chains are too interconnected to be managed with isolated inventory rules. MEIO provides a network-wide view of inventory, helping organizations balance service levels, costs, and risk across all echelons instead of optimizing each node separately.

By adopting MEIO, companies move from reactive firefighting to proactive decision-making. They gain clearer trade-offs, better inventory placement, and stronger operational efficiency as complexity grows.

Want to see how MEIO would work in your network? Book a demo with Sophus to evaluate multi-echelon safety stock, run fast what-if scenarios, and build an inventory strategy that improves service without inflating working capital.