A frontrunner in the international food sector, Lee Kum Kee, uses a complex network of more than 40 DCs, including CDCs and RDCs, to move goods globally. The corporation manages a complicated global network with the help of three critical production units. The sophisticated and crucial supply chain of Lee Kum Kee is the reason for its ongoing success in the highly competitive industry.

Challenges

Distribution optimization—from distribution centers to customers—has traditionally been the main emphasis of Lee Kum Kee’s supply chain management. Although it worked, this method failed to consider the benefits that possibly resulted from a broader view.

The business saw this coming and made a strategic change to optimize its supply chain from distribution hubs to raw material suppliers.

There were obstacles along the way:

- Minimal Exposure: Comprehensive optimization attempts were impeded by a lack of information on procuring raw materials and production processes.

The company must comprehensively understand its supply chain. Without knowing the origins of everything, how can we optimize?

- Coordination Complexity: There were logistical hurdles to overcome in coordinating across many suppliers, production facilities, and distribution sites.

Organizing across all of our distribution facilities and vendors is a nightmare, said the director of operations.

- Inventory Management: Meeting demand without overstocking was a major challenge that must be balanced across the network.

It’s not easy to keep your inventory levels at the appropriate level. We run the danger of running out of stock if we don’t have enough, yet having too much of anything ties up money.

- Integrating Technology: Difficulty with integrating several network-based technological platforms hampered data exchange and analysis.

Our systems are fragmented and outdated, said the IT manager. They are easier said than done to integrate for smooth data interchange.

Solution

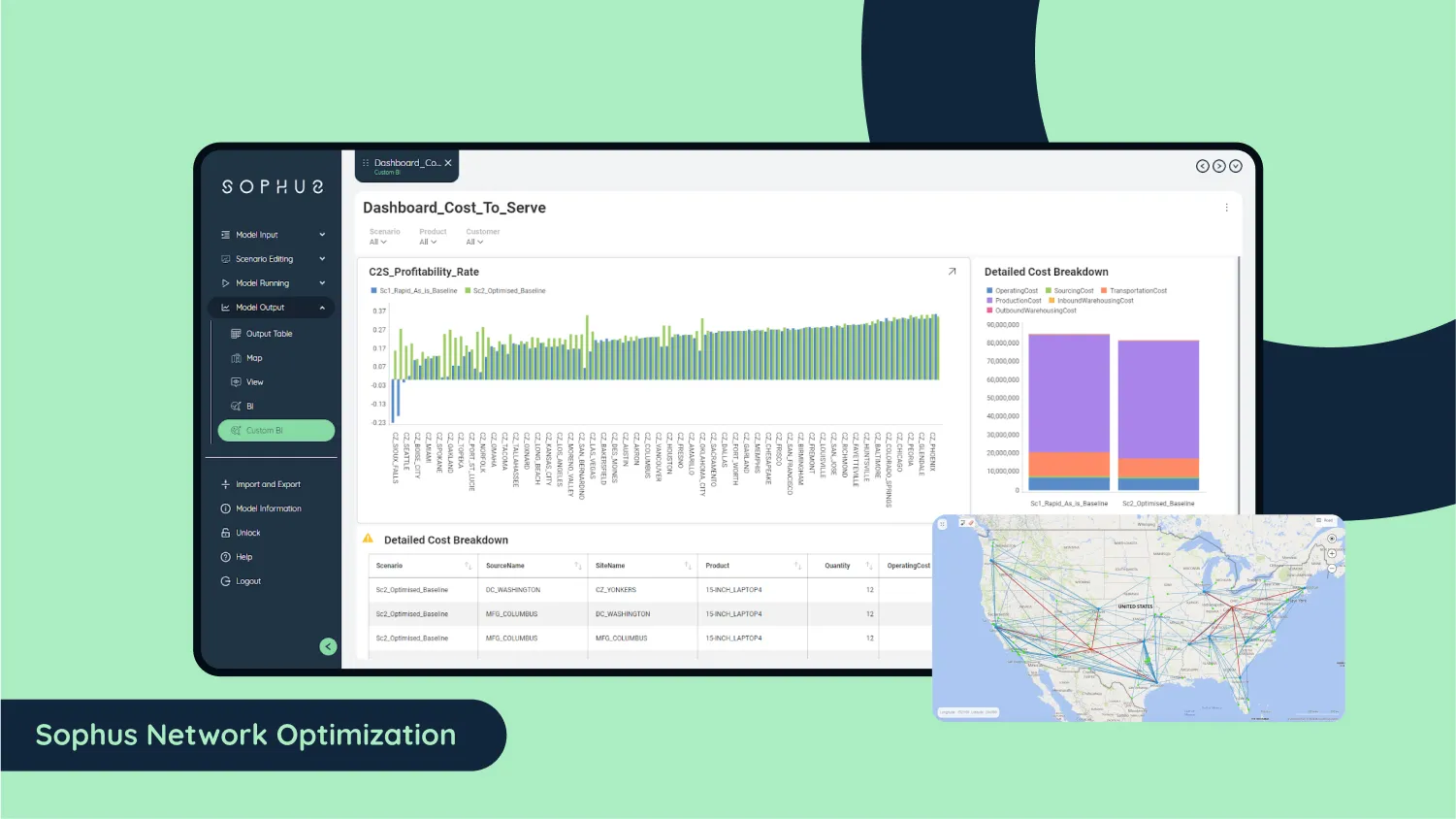

Lee Kum Kee teamed up with Sophus to tackle the issues plaguing their supply chain. Their activities were the target of the partnership’s efforts to improve efficiency and effectiveness. A complete network model that linked suppliers, production facilities, and distribution hubs was developed in close collaboration with the organization by Sophus.

Due to this methodology, Lee Kum Kee could see the big picture of its supply chain—from obtaining raw materials to delivering finished goods. The supply chain could communicate and share data more efficiently because of the facilitated data and system integration. It also offered helpful insights into supply chain performance and found ways to enhance it using advanced analytics and optimization methodologies.

Sophus also helped Lee Kum Kee with scenario planning and simulation exercises, which let the business see how various strategies may play out and help them make smarter choices.

Outcomes

With the help of the Sophus platform, Lee Kum Kee was able to optimize its network from beginning to finish, yielding priceless insights and results:

- Obtaining Raw Materials at a Low Cost: Guaranteed best procurement processes by identifying the most cost-effective suppliers for raw materials through rigorous analysis.

- Efficient Production Allocation: Distributed work most effectively, making the most of available production facilities while keeping expenses to a minimum.

- The Ideal Area Required for a Distribution Center: Enhanced operational efficiency and reduced transportation costs by determining the ideal footprint for distribution facilities.

- Potential Savings: Developed strategies to enhance supply chain management and streamline processes, resulting in savings exceeding $20 million.

Impressed by these achievements, Lee Kum Kee is moving forward with its supply chain strategy by launching a ‘Dynamic End-to-End Supply Chain Network’ project. Part of this effort is to keep the supply chain model up-to-date so that it can react instantly to changes in the outside world.

Lee Kum Kee can swiftly adjust to changes in demand, interruptions in the supply chain, or natural catastrophes since this project is dynamic. With the ability to update optimization results in the network within one hour, the organization can now navigate the complexity of the global supply chain landscape with remarkable agility.

Get in touch with Sophus today to start your path to supply chain excellence and unlock the potential of optimized networks.