A major challenge many supply chain network design professionals face nowadays is managing the vast amounts of data generated from diverse sources. This data has the potential to unlock insights critical to optimizing your network. However, without proper tools and techniques, the data scale and complexity can become overwhelming.

Nowadays many companies supply chain network design and modeling teams use – ETL (Extract, Transform, Load) Data Processing. It helps Supply chain design professionals to manage their data efficiently and build out their models correctly and efficiently. It does so by extracting data from various sources, transforming it into a unified format, and loading it into a central repository.

As supply chain network design becomes increasingly complex and data intensive, integrating ETL in your network design processes is no longer just beneficial but essential.

Understanding Supply Chain Network Design

A supply chain network includes all the parts involved in getting a product from the production units to the customers. This includes suppliers, manufacturers, distribution centers, and retailers, all linked by transportation routes. Each component plays a vital role in ensuring that goods move efficiently from inception to delivery.

Creating an effective supply chain network can be tough. Companies often struggle with unexpected changes in customer demand and interruptions in supply. They also need to find a balance between keeping costs low and maintaining high quality.

Moreover, quick decision-making is crucial. If it takes weeks or months to solve a problem, the solution might no longer be useful by the time it’s ready. Businesses must be quick and adaptable, using strong data analysis and making decisions in real time to stay relevant.

Quick Link: 7 Best Supply Chain Network Optimization Tools?

Critical Role of Data Processing in Supply Chain Network Design

Data processing plays a crucial role in supply chain network design and often 70-80% of the time on a network design project needs to be spent on data collection, validation and cleaning not on the network design modeling itself.

Overview of ETL Data Processing

ETL, which stands for Extract, Transform, and Load, is a process used in data handling. This involves taking data from different sources (Extract), cleaning and organizing it into a useful format (Transform), and then storing it in a system where it can be accessed and used (Load). This process ensures that the data is accurate and ready for analysis.

How ETL Data Processing Streamlines Supply Chain Network Design

ETL data processing makes modeling supply chain network design a lot more efficient by automating the collection and transformation of data, businesses can quickly gather insights from various sources.

This also means that the team can rapidly adjust to changes in the market or address issues as they arise, ensuring the supply chain network design models can be done in a matter of minutes or hours.

Advantages of Sophus’ Integrated ETL Data Processing

Sophus’ self developed ETL data processing ‘Dastro’ offers significant advantages that streamline and enhance supply chain network design process:

Ease of Configuration and Modification

The system is designed to be user-friendly, allowing businesses to easily configure and modify their data processes. This flexibility is crucial for adapting to new business requirements or changes in the operational environment without needing extensive technical support.

Seamless Integration

Since ‘Dastro’ ETL tool is part of Sophus platform instead of using a third party tool which eliminates the complexity and inefficiencies associated with managing multiple standalone systems. This integration simplifies the IT infrastructure, reducing errors and ensuring smooth operations.

Cloud-Based Solution

Sophus’ ETL is a 100% cloud based solution, first of its kind, all data is stored in the cloud, which means that it’s accessible from anywhere and doesn’t require local storage. This not only enhances security, as no sensitive data is stored on personal laptops, but also provides scalability and reliability

It enables you to expand your network design studies without concerns about data capacity or access issues. Another advantage of cloud-based solutions is the possibility of team collaboration. Multiple users could contribute to the same workflow concurrently.

Data Processing Capacity

Unlike Excel, which limits each sheet to approximately 1 million rows, and SQL Server Express, which imposes a 10GB limit per database, PostgreSQL and Dastro do not have these constraints. This enables users to handle much larger volumes of data, making it ideal for extensive datasets.

Automatic Data Audit Trail

Dastro automatically records every operation performed on the source data. This ensures repeatability and traceability, allowing users to track the entire workflow and identify the steps that produced a specific result.

Also Read: Top 7 Supply Chain Planning Mistakes and How to Avoid Them?

Real-Life Applications and Case Studies

Lee Kum Kee leveraged Sophus’ technology to significantly enhance its supply chain management. By adopting Sophus’ network model, Lee Kum Kee optimized its supply chain from raw material suppliers to distribution hubs. Their strategic enhancements led to substantial savings exceeding $20 million and the initiation of a dynamic, end-to-end supply chain network design that adapting quickly to market changes and potential disruption.

Such end-to-end dynamic network design can’t become realized without the highly effective ETL – ‘Dastro’, Dastro linked to its data sources and able to pull data automatically when there is a need to refresh the data and rerun the network model.

Such a process takes only 10 minutes to complete and becomes a critical part of Lee Kum Kee’s supply chain decision process.

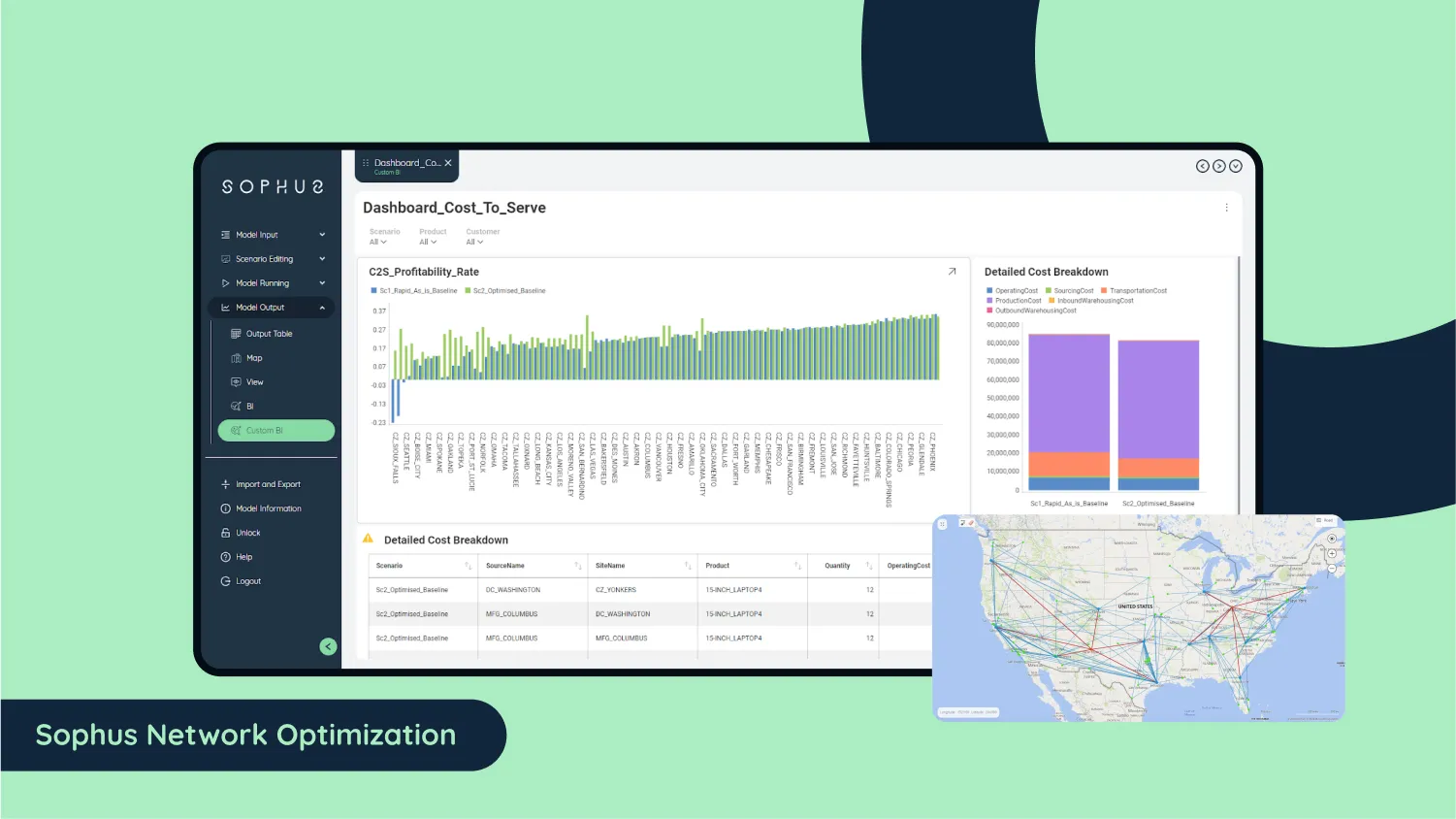

Sophus offers a comprehensive suite of solutions that enhance the entire supply chain, unlike other tools focused on specific areas. This integrated approach helps businesses tackle complex challenges by optimizing not just transportation and warehousing, but also production and sourcing.

Considerations for Choosing an ETL Solution in Supply Chain Management

When selecting an ETL solution for supply chain management, it’s crucial to consider several key factors that will impact its effectiveness and integration with your business operations.

Here are the primary considerations:

1. Importance of Integration and Seamless Data Flow

An ideal ETL solution should integrate seamlessly with existing systems within your organization. This integration enables a smooth flow of data across different departments and platforms, reducing the risk of data silos and inaccuracies.

A well-integrated ETL system ensures that data from various sources can be consolidated efficiently, providing a single source of truth that enhances decision-making and operational visibility.

2. Flexibility and Scalability of ETL Solutions

The chosen ETL solution must be flexible enough to adapt to changing business needs and scalable to handle increasing data volumes as the business grows. Cloud-based ETL solutions are particularly advantageous in this regard.

They offer the elasticity to scale resources up or down based on demand, which is cost-effective and ensures that your data processing capabilities can grow with your business without the need for significant upfront investments in hardware.

3. Cost and Resource Implications

Cost is a major consideration when implementing a new ETL solution. It’s important to evaluate not only the initial licensing or subscription costs but also the long-term operational costs associated with maintaining and scaling the system.

Additionally, consider the resources needed to manage the ETL process, including technical staff and training. An effective ETL solution should improve operational efficiency without requiring excessive ongoing expenses or complex resource management.

Summing up

ETL data processing is essential for optimizing supply chain network design. It ensures efficient operations and effective decision-making. By automating data handling, systems like Sophus enhance data accuracy and streamline operations.

They integrate seamlessly with existing platforms, improving responsiveness and reducing costs. Sophus’ cloud-based approach offers scalability and ease of configuration. All of these features make it a superior choice for businesses aiming to maintain competitive supply chains.

Contact Sophus today to begin improving your supply chain network design.