There are many challenges to overcome when managing the complexity of supply chain network design, particularly when it comes to considering actual shipment.

Supply chain professionals grapple with critical questions like, “If we wait for one more day to ship out, can we get to a higher rate break and lower the total cost?”

And then another pressing concern arises for supply chain designers: “how to consolidate orders for larger shipments once the network is decided. Should we wait for one more day?”

This challenge highlights how crucial cost and schedule factors are to shipment consolidation, but conventional network design techniques frequently fall short of offering adequate solutions.

In network modeling, assumptions are often based on average shipment size across a time horizon or simply assume everything is just full truckload shipments, but the reality is far from ideal. Average shipment size across a time horizon doesn’t get into the shipment level but rather an average cost per shipment * shipment, and that the average cost has to be calculated using databases or customized solutions. And when it comes to full truck load, The necessity to ship out when trucks are only partially full, at 50% or 60% capacity, poses a significant challenge,

Well, in network design tools those types of questions just can’t be answered,

Some people would say, let’s use vehicle route optimization algorithms to answer these questions. But to be honest vehicle route optimization is best to solve multi-stop pick up/drop off at a very small scale. As a heuristic algorithm, it can’t even handle tens of thousands of shipments. Nowadays companies would often have millions of shipments per week, and the vehicle route optimization algorithm simply can’t handle this scale.

That’s why Sophus X innovated out, and can effectively answer those questions with a new solution – called order assignment.

Let’s see how!

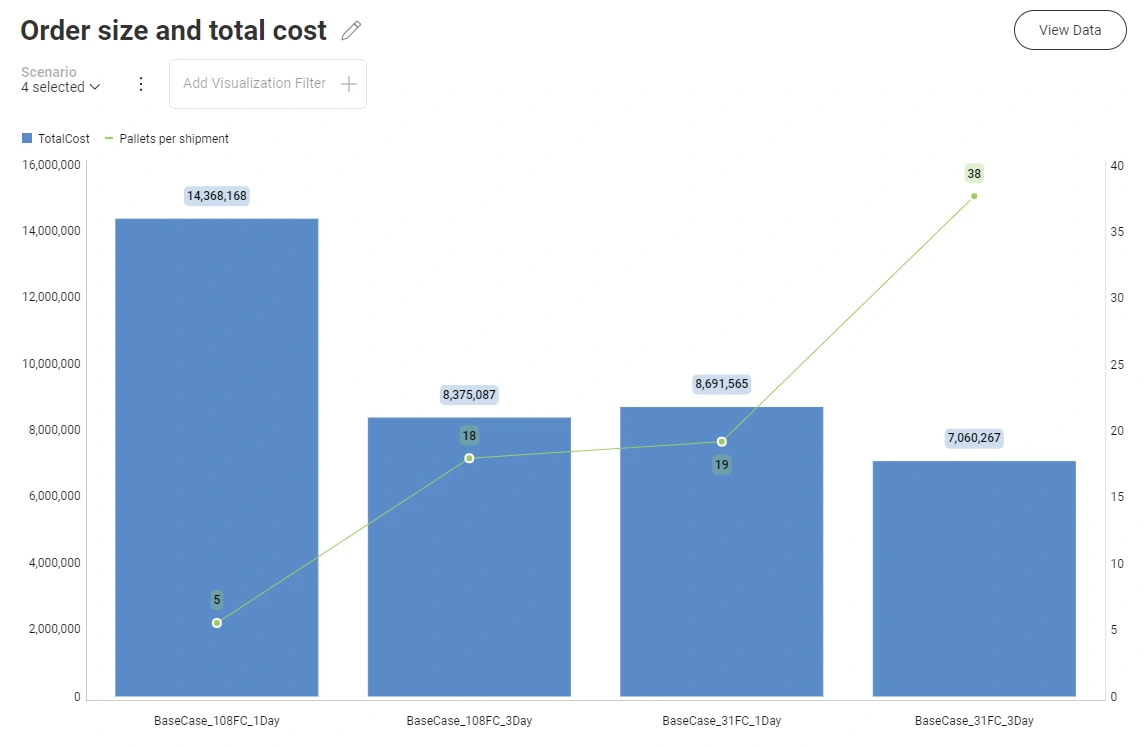

Figure. Example of relationship between order size and total transportation cost

Sophus X Order Assignment Capability: Streamlining Shipment Consolidation

Sophus X Order Assignment capability transforms the process of shipment consolidation by providing users with a comprehensive platform to input actual orders by date, earliest and latest pick-up and delivery dates, available lanes, and tier-based pricing by different shipment sizes. This feature enables Sophus X to intelligently consolidate orders into optimal shipments, considering various factors such as delivery timelines and cost efficiency.

Moreover, Sophus X accurately calculates actual shipment costs, integrating real-time data and sophisticated algorithms to provide users with precise cost predictions for each shipment.

Additionally, users have the flexibility to experiment with shipment timelines, allowing them to delay shipments by a day to explore potential cost savings or achieve higher rate breaks.

Figure. Before and after ship-to-location consolidation and impact on profitability. In the consolidated network on the right, there are fewer but larger destinations (notice the scale difference), as well as higher profitability (darker colors)

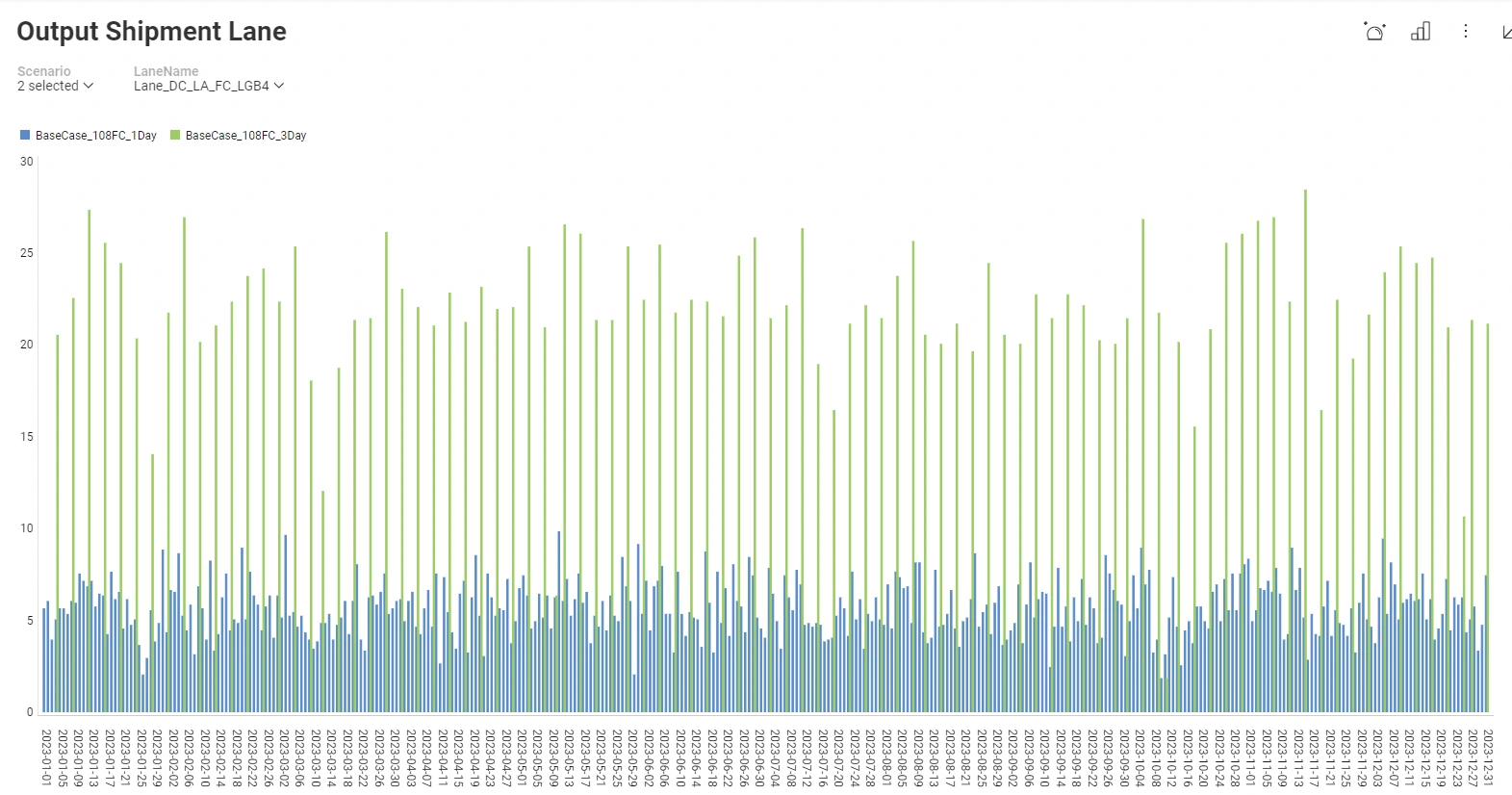

Figure. Comparing two scenarios with different service levels. With 3 days’ SLA, Sophus suggests fewer and larger shipments to save 40% transportation costs

Sophus X’s Order Assignment (OA) algorithm fills a crucial gap between classic network optimization (NO) and traditional optimization (TO) methods.

While NO cannot handle shipment-level modeling and TO is too slow for large datasets, OA efficiently processes shipment-level inputs and can handle millions of rows in the inputs, ensuring swift and efficient processing for even the largest datasets.

Sophus X Cost Optimization: Achieving Higher Rate Breaks

Sophus X empowers users to achieve higher rate breaks and optimize costs through its advanced algorithms and dynamic capabilities. By using Sophus X’s sophisticated model, users can input actual orders and shipment details to explore various scenarios and determine the most cost-effective shipping strategy.

Sophus X enables users to delay shipments by a day, allowing them to assess whether higher rate breaks can be reached and costs can be minimized.

Figure. Step-wise transportation rate in the input to model the economy of scale when consolidating shipments

This flexibility in shipment planning and optimization sets SophusX apart, providing supply chain professionals with actionable insights and strategies to achieve cost efficiencies and maximize savings.

See What Our Users Say About Sophus X

Case Study 1:

- Issue: Our client, a supply chain designer in a furniture company, faced challenges with the existing network design tools. They struggled to optimize shipment strategies and allocate resources effectively due to reliance on inaccurate cost calculations.

- Results: Upon implementing Sophus X’s order assignment algorithm, our client experienced significant improvements in shipment consolidation and cost optimization. They achieved nearly a 9% reduction in transportation costs while ensuring timely deliveries to thousands of stores nationwide.

“I am a supply chain designer in a furniture company. Our network is fairly straightforward with 4 RDCs delivering to thousands of stores nationally. In the past, I used network design tools to model the allocation between the DCs and stores based on optimal transportation cost.

However, there weren’t significant benefits as we had to rely on average per cubic cost per lane, which didn’t align with our actual transportation cost calculations. In our line of business, the most critical aspect of our network is consolidating orders from stores into larger shipments to lower costs without sacrificing service lead time.

Now, with Sophus X’s order assignment algorithm, we optimize order consolidation across our lanes to achieve bigger shipment sizes and FTL. This has resulted in nearly a 9% reduction in transportation costs.”

Case Study 2:

- Issue: Our client, a supply chain designer in a wholesale company, encountered difficulties in negotiating shipment terms with their customers (retailers). They lacked accurate cost impact assessments to support negotiation outcomes, leading to potential inefficiencies in their supply chain operations.

- Results: With Sophus X’s advanced capabilities, our client gained the ability to model cost impacts with 100% accuracy. This empowered their management team to enter negotiations fully informed, resulting in enhanced negotiation outcomes and improved overall supply chain efficiency.

“I am a supply chain designer in a wholesale company. We’ve been utilizing Sophus X’s order assignment algorithm to optimize order consolidation across our lanes for bigger shipment sizes and FTL.

Additionally, we often need to negotiate with our customers (retailers) for more or less frequent shipments or drop-off points. The challenge lies in providing our management with accurate cost impact assessments for these negotiations.”

Summing Up

SophusX addresses this by enabling us to model cost impacts with 100% accuracy, a capability unmatched by other tools. This ensures that our management can enter negotiations fully informed, enhancing our negotiation outcomes and overall supply chain efficiency.”

Hence, by addressing critical issues such as inaccurate cost calculations and lack of negotiation support, Sophus X empowers supply chain professionals to make informed decisions and achieve significant cost savings.

With Sophus X, users can streamline shipment consolidation, optimize costs, and enhance negotiation outcomes, leading to improved efficiency and competitiveness in the market.

As businesses continue to navigate the complexities of supply chain management, Sophus X stands as a reliable partner, providing innovative solutions to drive success and growth.