In business, unexpected issues can arise and create big problems. These problems can include things like not having enough materials or problems with getting things where they need to go on time. They can really mess up even the most well-organized businesses, costing them time and money, and making customers upset.

But there’s a way to handle these problems: Supply Chain Scenario Planning.

This method helps businesses predict and deal with problems before they happen. By thinking about different situations and making plans, companies can stay strong and overcome any challenge. Let’s take a brief look at supply chain scenario planning and talk about a few case studies as well.

What is Supply Chain Scenario Planning?

Supply chain scenario planning is all about getting ready for what might happen in the future. It’s like preparing for different possibilities and making plans in advance, just in case. This way, if something unexpected does occur, you’re already prepared and know what to do.

Long story short, scenario planning in Supply chain network design helps a company determine what could go wrong in its supply chain. This could be anything from transportation delays to suppliers going out of business or even global emergencies like pandemics. But by thinking ahead and devising strategies, businesses can manage these risks and keep things running smoothly, no matter what comes their way.

Types of Supply Chain Scenario Planning

Scenario planning in Supply chain network design doesn’t have a one-size-fits-all approach. There are various types, each with its unique focus and methods:

- Optimistic, Pessimistic, and Best Guess Scenarios: This involves creating three scenarios: optimistic, pessimistic, and best guess. Optimistic scenarios consider the best outcomes, like a sudden demand surge. Pessimistic scenarios explore potential pitfalls, like a market crash. Best guess provides a balanced view based on current trends.

- Good vs. Bad Scenarios: This focuses on extremes, considering the most optimistic (good) and pessimistic (bad) scenarios. For instance, a good scenario might be a successful product launch, while a bad one could be a product recall.

- Arrayed Scenarios: This method is quantitative, looking at a range of alternatives based on specific criteria. For example, an energy company might plan for slight, moderate, or severe fluctuations in oil prices.

- Independent Themed Scenarios: This strategic approach focuses on individual categories of change, like technology, the environment, or market trends. For example, a tech company might consider scenarios for breakthroughs in artificial intelligence or quantum computing.

Significance of Supply Chain Scenario Planning

Supply chain scenario planning is like having a crystal ball for businesses – it helps them foresee and understand possible risks. Here’s why it’s essential:

- In-depth analysis: Scenario planning lets businesses look closely at different outcomes, helping leaders make smart choices.

- Proactive problem-solving: By spotting issues early, scenario planning helps businesses avoid problems and deal with challenges effectively.

- Fostering diversity of thought: It encourages different viewpoints, which leads to creative problem-solving and avoids everyone thinking the same way.

- Challenging the status quo: Scenario planning encourages businesses to think outside the box and consider new ideas, going beyond what’s usually done.

- Early warning system: It helps businesses catch potential problems before they get big so they can fix them early and prevent them from getting worse.

- Contingency planning: Scenario planning helps businesses create backup plans so they can take quick action if unexpected problems arise.

- Future-proofing: Unlike traditional forecasting, scenario planning helps businesses prepare for the future by looking ahead and adapting to changes in their environment.

By using advanced technology tools such as Sophus Technology for scenario planning, businesses can improve their ability to analyze information, make decisions faster, and stay ahead of competitors.

With Sophus Technology, companies can feel more prepared for whatever challenges come their way. Get started with a Free Demo today.

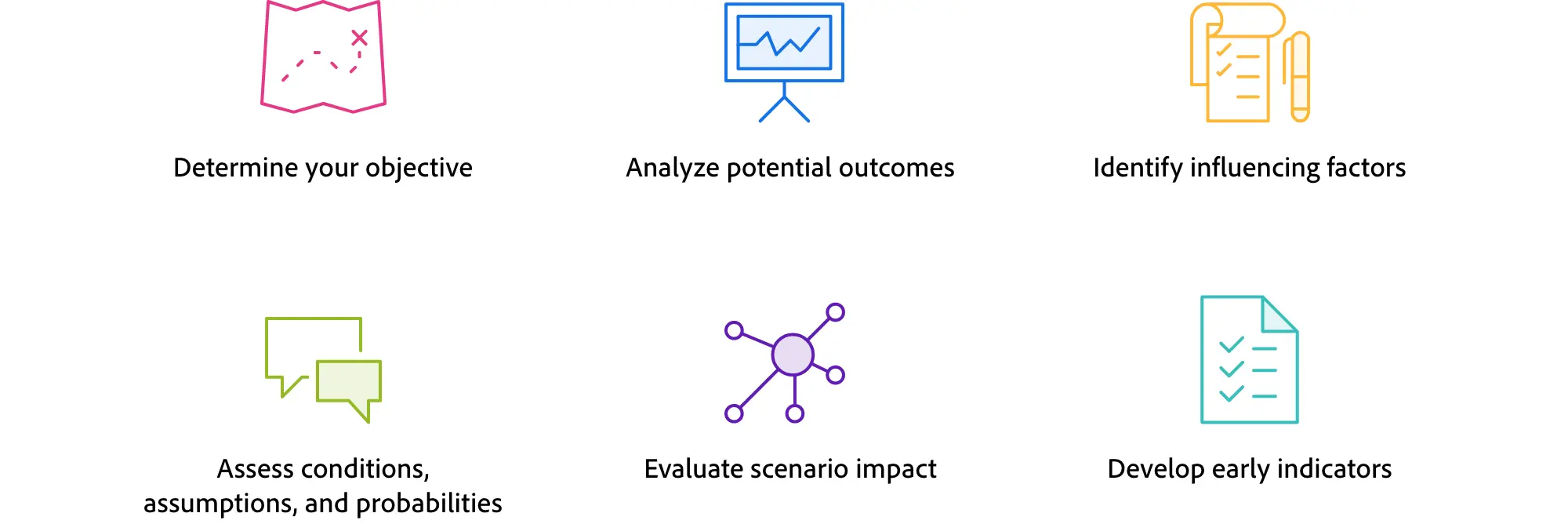

6 Steps of The Scenario Planning Process

The scenario planning in Supply chain network design involves six steps. Here are the six steps of the scenario planning process:

1. Define Your Objective

The first step in scenario planning is to establish a clear objective for your organization. This objective could be a long-term vision, a strategic goal, or a specific target you aim to achieve within a defined timeframe.

It’s essential to align this objective with your overall business strategy and consider where you envision your organization in the next three to five years. Defining your objective provides a clear direction and purpose for the scenario planning exercise.

2. Analyze Potential Outcomes

Once you’ve defined your objective, the next step is to analyze the potential outcomes of your current actions and decisions. This involves evaluating how different scenarios may unfold based on various factors and assumptions.

It’s crucial to consider the implications of each scenario on your organization’s goals, operations, stakeholders, and external environment. This analysis helps you understand the risks and opportunities associated with different courses of action.

3. Identify Influencing Factors

In this step, you identify the key factors that could influence the direction of your organization. These factors may include internal elements, such as organizational changes, capabilities, and resources.

It also includes external factors such as market trends, technological advancements, regulatory changes, and competitive dynamics. By understanding these influencing factors, you gain insights into the forces shaping your business environment and driving potential scenarios.

4. Assess Conditions, Assumptions, and Probabilities

Once you’ve identified the influencing factors, you assess the conditions, assumptions, and probabilities associated with each potential scenario. This involves creating multiple scenarios or narratives that describe different future states of the environment in which your organization operates.

Each scenario represents a plausible storyline based on a combination of factors and assumptions. It’s essential to evaluate the likelihood or probability of each scenario occurring and focus on the most probable ones for resource allocation and strategic planning.

5. Evaluate Scenario Impact

In this step, you evaluate the potential impact of each scenario on your organization. This involves considering the implications of each scenario for your business strategy, operations, finances, customers, employees, and other stakeholders.

You assess the risks, opportunities, challenges, and trade-offs associated with each scenario and identify the necessary actions or strategies to mitigate risks and capitalize on opportunities. This evaluation helps you make informed decisions and prepare contingency plans for different eventualities.

6. Develop Early Indicators

The final step in the scenario planning process is to develop early indicators or signals for each scenario. These indicators serve as triggers or warning signs that alert you to changes in the business environment and potential shifts in scenario dynamics.

By identifying early indicators, you enable proactive management and decision-making, allowing your organization to anticipate emerging trends, threats, or opportunities and respond promptly. Developing early indicators helps you stay agile, adaptive, and resilient in a dynamic and uncertain world.

Quick Read: Best Practices in Supply Chain Design – Optimizing Efficiency

Scenario Planning for the Known: What to Expect?

Decision making has become more complex than ever, particularly when it involves significant operational changes such as shutting down a production line or altering the replenishment frequency from plants to warehouses.

These decisions are not made in isolation; they reverberate through every facet of an organization, impacting cost, service, inventory levels, and even carbon emissions.

Impact of Scenario Planning for the Known

Scenario planning for known challenges is like setting the stage for a series of strategic plays. It’s about predicting the impact of specific actions before they’re implemented.

For instance, consider the decision to shut down a production line or to adjust the replenishment strategy from plants to warehouses.

Such decisions can have profound implications:

Impact on Cost

Reducing the number of production lines or altering replenishment strategies can lead to significant cost savings in terms of reduced operational expenses and lower labor costs.

However, it could also result in upfront costs such as severance pay or investments in new logistical arrangements. Scenario planning helps in balancing these factors, providing a clear view of the long-term financial implications.

Impact on Service

Changing the frequency of replenishments can affect service levels. A reduced frequency might lead to savings in transportation costs but could risk stockouts, affecting customer satisfaction.

Conversely, increasing replenishment frequency might improve service levels but at a higher cost. Through scenario planning, organizations can find the sweet spot that optimizes both service levels and costs.

Impact on Inventory Levels

Altering production and replenishment strategies directly affects inventory levels. A reduction in production might lower inventory costs but could also lead to a lack of product availability.

Scenario planning allows for a detailed analysis of inventory needs versus costs, ensuring that inventory levels are optimized for both efficiency and market demand.

Impact on Carbon Emissions

Today’s businesses are increasingly accountable for their environmental impact. Changing operational strategies can have significant effects on carbon emissions.

For example, reducing replenishment frequency might lower emissions by decreasing the number of transportation trips required. Scenario planning provides insights into how operational decisions align with sustainability goals, helping organizations make environmentally responsible choices.

Quick Read: Supply Chain Carbon Neutrality Strategies | Carbon Emission Offset Optimization

Conclusion

In conclusion, supply chain scenario planning is an important strategy for businesses to prepare for unforeseen challenges and opportunities.

By anticipating potential scenarios, analyzing their impacts, and creating proactive strategies, organizations can navigate uncertainties with confidence.

With the support of innovative technology solutions like Sophus Technology, companies can streamline their scenario planning processes and confidently prepare for whatever challenges lie ahead.