Companies need to work smarter and more efficiently in today’s fast-moving business world. This raises a big question:

How can businesses effectively manage their supply chains to meet evolving customer demands while minimising costs?

The answer lies in supply chain network design and optimisation. By carefully choosing where warehouses are placed, planning out transport routes, and managing stock levels wisely, businesses can make their operations run better and save money at the same time.

Using this intelligent approach brings big rewards.

When orders are handled well within inventory systems, companies could see a 25% boost in their productivity, use their space 20% better, and improve their stock use by 30%.

In this article, we explore the transformative impact of supply chain design on modern business operations.

Understanding Supply Chain Network Design

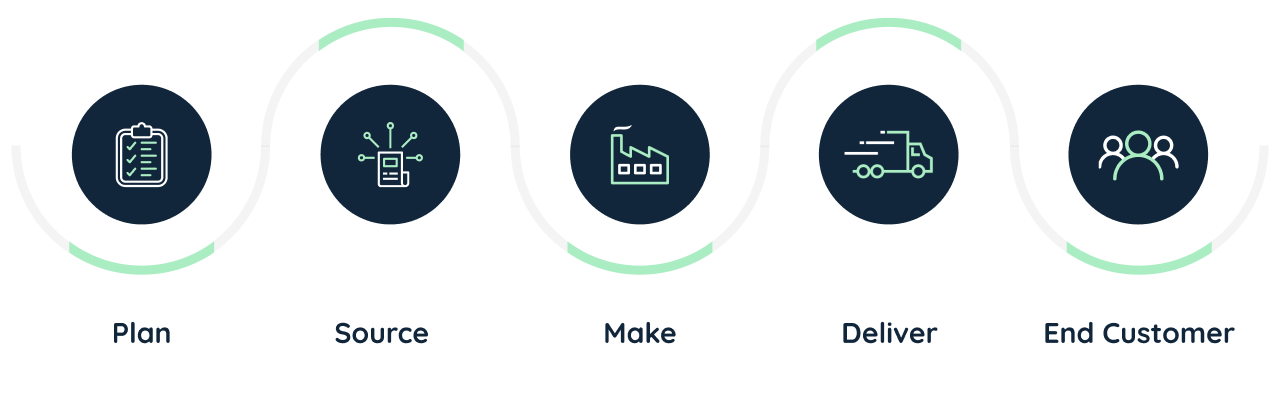

Supply Chain Network Design is all about planning and improving the parts of a supply chain.

This means figuring out the best warehouse, factory, and distribution centre setup. It also includes how products, information, and money move between these places.

According to Herbert Simon, design is about making plans to change things from how they are now to how we want them to be. At Sophus Technology, we think the same way about designing supply chain networks.

We see it as shaping the whole supply chain process so it works best for what your organisation wants and needs.

In supply chain design and optimisation process, several crucial elements come into play:

Network Structure:

This involves figuring out how many facilities you need and where they should be located, like warehouses, distribution centres, and manufacturing plants. The goal is to ensure they’re close enough to suppliers and customers to reduce transportation costs.

Inventory Placement:

You have to be strategic about where you place your inventory across the network. This means placing it in spots where it can meet changes in demand, prevent running out of stock, and keep carrying costs low.

Transportation Routes:

Finding the best routes to move your products between different points in the network is key. You’ll consider the distance, what mode of transport to use, and how much it’ll cost to move goods around.

Information Systems:

Strong information systems are crucial for keeping everything running smoothly. These systems help with communication and coordination within the supply chain network design, allowing for real-time tracking of inventory and shipments.

Risk Management:

Lastly, you’ve got to assess and deal with potential risks that could disrupt your plans. This means looking out for supply disruptions, changes in demand, or other factors like geopolitical issues that could affect the way your network operates.

The main aim is to make everything work more smoothly, cut down on expenses, and provide better service by making sure the supply chain matches what the company wants to achieve.

When designing a supply network, things like customer demand trends, shipping costs, keeping track of inventory levels, and ways to handle potential problems are all taken into account. This helps create a flexible and robust network that can adapt well to changes in the market.

Benefits of Supply Chain Network Optimisation

Supply chain design is not just a matter of tweaking operations – it’s about building a flexible and resilient network that can adapt to whatever the future holds.

Let’s have a look at notable benefits of supply chain network design and optimisation:

Cost Reduction

Improving how the supply chain works means finding and fixing issues or unnecessary steps in moving goods, managing stock, and running facilities. Companies can significantly cut costs by combining shipments to send fewer of them, making transport faster, and arranging warehouses better.

Also, by making processes smoother and keeping less inventory with improved demand predictions and stock management methods, businesses can save a lot on the expenses of holding inventory and the money needed to run day-to-day operations.

Improved Customer Service

A good supply chain network design helps businesses better and more reliably meet their customers’ needs. Companies can make their customers happier and more loyal by cutting down on wait times, reducing the chances of running out of stock, and ensuring orders are filled correctly.

Also, seeing what’s in stock and how orders are doing in real time lets businesses keep their customers up-to-date about when they’ll get their products, improving customer service even more.

Enhanced Agility and Flexibility

In today’s fast-changing business world, adapting quickly and flexibly is very important. This helps businesses deal with unexpected changes and challenges.

Improving the supply chain can help companies become stronger and more able to adjust.

This means setting up adaptable distribution methods, using quick production methods, and having strong plans in place to reduce problems caused by natural disasters, political issues, or trouble getting supplies.

Better Decision-Making

Supply Chain Network Design and Optimisation helps companies make better decisions using intelligent data analysis and planning methods. It allows them to better understand their supply chain, find ways to make it more efficient, and test different plans to see how changes might affect things.

This leads to more intelligent choices about stock levels, when to make products, how goods are moved, and how to work with suppliers. As a result, companies can work more smoothly and do better overall.

Competitive Advantage

A good supply chain network design can help a business stand out and do better than others. If a company can deliver its products quickly, reliably, and cheaply, it can set itself apart from competitors.

Also, if the supply chain works well, businesses can react faster to customer demands, follow market changes more closely, and handle competition better.

This means they’re more likely to succeed and keep doing well in a tough market over time.

Sustainable Operations

Improving supply chains can help the environment and encourage companies to act more responsibly. By choosing better routes for transportation, using less fuel, and cutting down on harmful gases released into the air, businesses can reduce their harm to nature.

Also, companies use fewer resources by keeping just enough stock and cutting down on waste in their processes. This supports recycling and reuse ideas, making operations kinder to our planet.

Strategic Alignment

It is really important to ensure that the way we manage supplies and deliveries aligns with our main business goals if we are to succeed in the long run.

When businesses make supply chain choices that support their big-picture aims, they use resources wisely, spend money in ways that match these goals, and set up their supply chain to be a significant factor in making the business successful.

This means planning supply chain actions based on customer needs, monitoring market changes and competition, and smoothly collaborating with different parts of the company.

Steps to Achieve Supply Chain Network Optimisation

These steps are essential to ensure the supply chain works smoothly and efficiently. Every step helps find ways to get better, set clear goals, look for new solutions, and implement good plans like our supply chain network design and optimisation.

By paying attention to these steps, companies can tackle problems early on, work more effectively, and stand out in the fast-changing business world. It’s crucial to use these plans well to grow steadily, use resources wisely, and keep up with what customers and people want.

Here are the steps to achieve supply chain network optimisation:

Analysing the Current Network

Look at the current setup for moving goods, including buildings, paths used for transport, and how items are kept track of. Find parts that aren’t working well, places where things get stuck or slow down, and spots that could be improved.

Use tools and methods to study data to understand how well everything works.

Setting Optimisation Goals

Set clear goals for improving the network, ensuring they match the main business aims and plans. Choose important metrics (KPIs) to track how well these improvements work, such as saving money, faster delivery, or happier customers.

Put these goals in order of priority based on how crucial they are to the company and how much they could positively change the supply chain network.

Generating Alternate Network Designs

Create different network plans using advanced computer programs and smart methods. Compare various mixes of buildings, travel paths, and stock management methods to find the best options.

Check how possible, cost-friendly, and practical each plan is.

Implementing Optimised Network Design

Choose the best network design after comparing different options. Update the infrastructure, working methods, and systems to implement this chosen design.

Work closely with everyone involved and partners in the supply chain to ensure everything works well together and meets business goals.

Keep an eye on the network design and make changes when needed because of shifts in market trends, what customers want, and how operations are run.

Why Sophus Technology for Supply Chain Network Design?

Sophus Technology offers a compelling platform for supply chain network design and planning.

Sophus Technology combines technology, data automation, and collaborative features to enhance supply chain efficiency and effectiveness. Whether securing production supply, optimising distribution networks, or managing capacities, Sophus has you covered!

Here’s why it stands out:

Advanced Technologies

Sophus harnesses cutting-edge technologies such as data modelling, transformation, AI/ML, optimisation, and simulation. These tools empower every stage of the supply chain, including procurement, manufacturing, inventory management, logistics, and customer fulfilment.

Comprehensive Platform

Sophus provides a one-stop solution for supply chain design and planning. Their Sophus X platform integrates hundreds of algorithms and programs into a unified data model. It’s a cloud-based platform, ensuring easy access and flexibility.

Data Automation & Decision App Building:

- Dastro: SophusX includes a data automation module called “Dastro.” It automatically refreshes, cleans, and prepares data sets, ensuring accuracy and efficiency.

- Workbench: The decision app building feature allows users to create data workflows easily. These workflows can be shared and accessed across teams, promoting collaboration.

Mathematical Algorithms

Sophus operates with the fastest mathematical algorithms, enabling efficient supply chain optimisation and decision-making.

Case Studies of Successful Supply Chain Network Optimisation

Companies use Supply Chain Network Design and Optimisation to get great results. They look at their networks and set goals to improve them, finding areas that need improvement. Then, they create different network plans with special software, considering where facilities are and how goods are transported.

Let’s have a look at some of the real world examples of Supply chain network design:

Optimising African Supply Chains: Hisense Case Study

Hisense, a big company that makes electronics and appliances, used high-tech methods to improve how they get their products around Africa. They used SophusX with machine learning—a type of intelligent computer program—to become more agile and efficient. These programs helped them predict what customers want better, manage stock levels well, and make transporting goods cheaper and faster.

This led to Hisense being able to see into their supply chain more clearly, which meant they could handle their inventory smarter and cut costs. They also started using a digital model of their supply chain that let them test out strategies before implementing them in the real world.

This kept making things better over time. All these steps helped Hisense do better than its competitors by achieving superior results through constant innovation.

Optimising European Supply Chains: The LONGI-Sophus Collaboration

Sophus Technology is leading the way in improving LONGI’s supply chain in Europe. As LONGI proliferates, it focuses on improving its network to enhance its service delivery.

Working with Sophus creates a more efficient supply chain that plans the best paths from where products are made to where they’re sent out. This intelligent planning saves millions of dollars and strengthens LONGI in the market.

Sophus’s work shows its dedication to helping worldwide companies make smarter choices about their supply chains.

Conclusion: Efficiency with Supply Chain Network Design

Supply Chain Network Design and Optimisation help businesses work more efficiently and stay ahead of the competition.

By looking closely at their current setup, deciding on what they want to achieve, considering different options, and putting in place the best networks, companies can save a lot of money, offer better service, and quickly adapt to changes.

If you want to improve your supply chain and make the most out of your business operations, check out Sophus’s wide range of solutions today.