Most inventory and replenishment processes still depend on large cross-functional teams and long chains of tools. The workflow is so entangled that improving it becomes a challenge on its own.

Demand patterns shift quickly. Lead times stretch without warning. Supplier reliability changes from month to month. Static rules simply cannot keep inventory “just right.”

Planners continue to rely on disconnected spreadsheets, heavy planning systems, fixed policies, and old averages across thousands of SKUs. With so much uncertainty and so many manual touchpoints, how can any company truly manage inventory optimization instead of repeating what it has always done?

Since AI has taken over parts of this process, the experience has become smoother and more predictable. AI learns from real-time patterns, adjusts stocking logic instantly, and keeps replenishment aligned with what’s actually happening on the ground. According to McKinsey & Company, embedding AI in distribution operations can reduce inventory by 20-30%, along with other cost savings in logistics and procurement.

For planners, it feels like having a system that quietly fixes issues before they turn into problems. This is how AI becomes the invisible hand guiding modern supply chains toward smarter, more stable decisions.

Why is Inventory Imbalance a Big Problem for Supply Chains?

Inventory is always a balancing act. You don’t want too much, because it locks cash. You don’t want too little, because it hurts service. But every company eventually runs into the same trade-off triangle: availability, working capital, and excess. You can protect two, but the third one will suffer.

When the balance breaks, the symptoms show up fast:

- Excess stock piles up on slow-moving items and eats shelf space.

- High-volume SKUs run out and affect customer service.

- Teams rush into emergency transfers and pay for expensive expedited replenishment.

These problems don’t stay small. They grow into lost sales, higher operating costs, and pressure on cash flow.

Why Traditional Inventory Planning Methods Don’t Work Today

Traditional planning runs on fixed rules and slow cycles, so it can’t keep up with fast-moving demand and supply changes. Here’s where it breaks:

- Fixed reorder points: They stay the same for the whole month or quarter and ignore weekly demand changes. This makes the system react too late to spikes and keep ordering during drops.

- No end-to-end cost view: Planners cannot see transport cost, handling cost, MOQs, service levels, lead-time risk, and working capital together. They make decisions from only one angle.

- Frozen rule-based logic: When supplier reliability or lead times shift, the rules don’t update. This leads to sudden stockouts or unnecessary safety stock.

- Missed seasonality: Old models rely on past averages and fail to detect new buying behavior or early demand changes. Imbalance spreads quickly.

- Slow monthly cycles: Demand shifts weekly, but planning reviews happen monthly. Teams end up reacting late and firefighting issues.

- Siloed tools: Forecasting, replenishment, and cost data sit in separate systems. Planners work with incomplete information.

- Manual overrides: Gut-feel adjustments fix short-term problems but create uneven stocking across thousands of SKUs.

How AI Improves Inventory Balance Across the Supply Chain

AI brings a more flexible, data-driven approach to inventory balance, replacing static rules with decisions that update in real time and adjust to the full supply chain context.

Demand-Informed Replenishment Logic

AI links replenishment decisions directly to real demand behavior. Instead of following fixed rules, the system looks at live sales signals and current inventory levels before deciding what to order next. This keeps replenishment aligned with what customers are buying right now not what they were buying last month.

The engine also picks up micro-patterns that are easy for humans to miss. Small shifts after a promotion, changes in regional buying behavior, or even cannibalization between related SKUs all influence how much stock is replenished.

Dynamic Safety Stock Calculations

Safety stock becomes smarter because the buffer is recalculated for every SKU-location pair. AI uses real lead-time variability, actual service-level targets, and demand uncertainty to decide how much buffer each node needs — not just an outdated formula.

The model also watches vendor performance and backorder trends. When a supplier starts shipping late or variability increases, buffer levels increase automatically. When stability returns, the buffer is reduced to avoid excess.

This mirrors real-world results seen in large pharma supply chains, where Sophus helped bring SKUs down from more than 200 days of supply back to a healthy balance by adjusting safety stock at each node rather than applying a single global rule.

Cross-Location Inventory Optimization

AI views the network as a whole, not as isolated warehouses. It identifies which regions have surplus stock and which regions are at risk, then recommends the most efficient way to close the gap. Sometimes that means a simple transfer. Other times it means a blended approach: transfer part of the requirement and reorder the rest.

For example, if Region B needs 500 units, AI might notice Region A has 300 units in excess. Instead of placing a full 500-unit order, the system proposes moving 300 from A and ordering only 200 more for A. This reduces inbound costs, prevents new excess, and helps maintain balance without inflating working capital.

Lead-Time-Aware Reorder Decisions

AI does not treat lead time as a fixed number. It learns the real pattern behind every supplier, lane, and material. If a vendor consistently trends late by three days, the system knows this before planners feel the impact.

Instead of waiting for shortages, AI adjusts the reorder date, increases early POs, or shifts a portion of the volume to a more reliable supplier. It forecasts the arrival risk for every open order, giving planners a clear picture of where delays may occur and what actions can prevent disruption.

How Sophus Helps in AI-Driven Replenishment Optimization

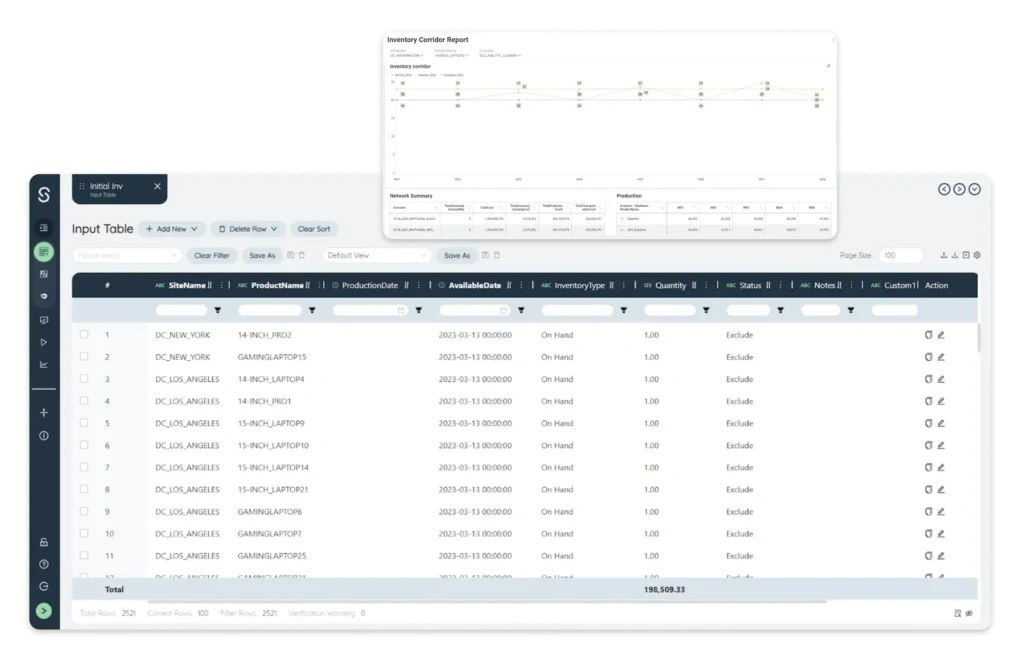

Sophus helps companies improve inventory levels through advanced replenishment optimization, ensuring the right frequency and quantity of stock movement across DCs and sites. It also balances these decisions with key cost factors like sourcing cost, transportation cost, and storage cost to produce the most efficient replenishment and stock-transfer plan.

Continuous Planning Engine for Inventory Teams

Sophus recalibrates inventory and replenishment strategies every day. It uses embedded demand forecasts, real-time inventory logic, and full network constraints to update decisions automatically. This continuous approach supports inventory optimization by keeping stock levels aligned with true demand instead of outdated rules.

Sophus handles thousands of SKUs across multiple nodes without manual batch runs, giving planners a live, always-current view of what needs to move, when, and why.

Embedded Scenario Modeling

Sophus includes built-in what-if tools that let planners test different situations before they happen. Teams can model lead-time changes, sudden demand surges, supplier disruptions, or new stocking policies.

This gives inventory managers the ability to plan ahead instead of reacting late, making the entire process more stable and predictable.

Deployment That Enhances the Current Planning Process

Sophus fits into the systems companies already use. It integrates smoothly with ERP, planning, and WMS platforms, adding a decision-intelligence layer on top of existing workflows.

This helps teams improve how they plan inventory without replacing their entire planning stack.

A great example is Hisense, which adopted Sophus for AI-driven demand forecasting. Using our GBM algorithm, Hisense achieved 70% forecast accuracy at the SKU, weekly, and channel level, making planning significantly faster and more precise.

Getting Started with AI-Powered Replenishment

Identify the Right SKU Segment to Start

The best way to begin is by focusing on SKUs where AI delivers immediate value. High-variability, high-volume, or high-margin items respond quickly to AI-based improvements because even small changes in accuracy create a meaningful impact. Starting here lets teams see results early without overwhelming the process.

Connect Forecasting and Inventory

AI works best when forecasting and replenishment are connected, not isolated in separate systems. When demand signals flow directly into inventory logic, the replenishment engine can adjust faster and with more confidence. This is why modern platforms unify both streams so planners work from one source of truth.

Don’t Automate Overnight—Pilot, Shadow, Scale

The strongest implementations begin in shadow mode, where AI recommendations run alongside the current manual process. Teams compare outcomes, validate improvements, and adjust thresholds before automating decisions. Once the results are proven, the system can scale across more SKUs, locations, and planning cycles with low risk and high stability.

Inventory planning will always be mission-critical, but it no longer needs to drain teams with nonstop manual work. AI enhances their judgment by making every decision smarter, faster, and more consistent.

Platforms like test.sophus.ai/ work quietly in the background, constantly fine-tuning replenishment, safety stock, and network flows so the entire system stays balanced. The result is a supply chain that runs with fewer surprises, fewer fire drills, and a much smoother experience for both planners and customers.

If you want to see how AI-driven replenishment can improve your network, reach out to us. Book a meeting with Sophus and explore how your inventory planning can become simpler, faster, and far more predictable.

FAQs

How does AI balance inventory across multiple locations without overstocking or stockouts?

AI looks at demand, stock levels, and lead times across every warehouse at the same time. It identifies where there is extra stock and where there is risk of running out. This helps the system make better optimization of inventory decisions before problems grow.

AI can also recommend transfers between sites to avoid new orders. The result is smoother inventory optimization with fewer stockouts and less overstocking.

What role does demand forecasting play in AI-driven inventory optimization?

Demand forecasting is the starting point for all inventory optimization. AI studies patterns, seasonality, promotions, and new buying behavior to predict what customers will need.

These forecasts guide decisions on replenishment quantity, timing, and safety stock. When demand is more accurate, optimization of inventory becomes easier. It keeps stock levels aligned with real demand instead of outdated averages.

How can AI reduce carrying costs while maintaining service levels?

AI monitors demand changes, supplier reliability, and product behavior to keep stock at the right level—not too high, not too low. This avoids excess that drives up storage and carrying costs.

At the same time, AI protects service levels by predicting where shortages might happen and adjusting orders early. By improving optimization inventory, companies hold less stock but still meet customer needs. This balance keeps operations efficient and responsive.

How does AI decide replenishment frequency for different products and sites?

AI checks demand velocity, volatility, lead times, and risk for each item at every location. Products that move fast or shift often get more frequent updates, while stable items get fewer. This makes inventory replenishment smarter and more responsive. The system also looks at costs, so replenishment frequency fits both the demand pattern and the budget. This creates steady, balanced stock across the network.

What is multi-echelon replenishment and how does AI improve it?

Multi-echelon replenishment means managing stock across several layers—like suppliers, DCs, and stores—at the same time. AI helps by seeing how one layer affects the others, which improves overall optimization of inventory. It adjusts orders so upstream and downstream nodes stay in sync. This prevents one site from being overloaded while another runs dry. With AI, multi-echelon plans become faster, clearer, and more cost-effective.

How can AI align replenishment with profitability goals instead of just refilling stock?

AI doesn’t treat every product the same. It looks at margins, demand value, and the cost of carrying stock. High-value items may get tighter inventory optimization, while low-margin items may get fewer replenishment cycles. This helps the business focus on products that drive profit.

What scenarios can AI simulate to prepare replenishment plans for demand surges or supplier delays?

AI can simulate demand spikes, regional surges, supplier delays, transportation issues, or seasonal changes. These scenarios help teams see how optimization of inventory will hold up under pressure. The system tests different replenishment options before problems happen. This means companies can plan for sudden changes instead of reacting too late. It keeps inventory replenishment steady, even when conditions shift quickly.