What happens when your supply chain relies on outdated, manual processes? How do you handle sudden changes in demand or rising transportation costs due to inefficient routes?

Without an automated supply chain network design, companies often struggle with slow decision-making, inaccurate demand forecasts, and poor visibility into their operations.

These issues can lead to higher costs and missed opportunities, making it hard to stay competitive.

So, what’s the solution?

Implementing real-time network design and scenario planning allows companies to optimize their supply chains, reduce costs, and quickly adapt to market changes.

This approach not only addresses the common challenges of manual processes but also keeps your supply chain agile, efficient, and ready to meet business demands.

An Overview of Automated Supply chain Network Design

Automated supply chain network design is a modern method that uses advanced technology and data to improve how supply chains work. It helps businesses enhance efficiency, cut costs, and quickly adapt to changes.

This approach gathers data from various sources and uses smart analytics to give a clear view of the supply chain. It also includes real-time monitoring to track shipments and inventory, allowing businesses to spot and address issues as they occur.

The benefits are significant:

- Optimizes how resources are used across the supply chain.

- Lowers costs by improving inventory levels and turnover.

- Speeds up delivery times to meet customer expectations more effectively.

- Enhances service levels and reliability for a better customer experience.

- Enables businesses to prepare for various situations and make quick, informed decisions to manage disruptions and seize new opportunities.

Components of Automated Supply Chain Network Design

Here are some of the must have components in an automated supply chain network design

Data Collection and Integration

The first step in automating your supply chain is gathering data from all parts of your operation, like suppliers, transportation, and customer orders. Integrating this data into one system gives everyone in the business a clear and up-to-date view, helping to make smarter decisions.

Advanced Analytics and Algorithms

Advanced analytics and smart algorithms are key to making your supply chain more efficient. These tools analyze data to find trends, predict demand, and suggest the best ways to manage inventory and shipping. By using these insights, businesses can cut costs and better handle changes in the market.

Real-Time Monitoring Systems

Real-time monitoring systems keep an eye on everything happening in your supply chain, from tracking shipments to managing inventory levels. These systems let you see issues as they arise, so you can quickly fix them and keep your operations running smoothly.

Scenario Planning Tools

Scenario planning tools help you prepare for the unexpected by simulating different situations, like sudden demand spikes or supply chain disruptions. By exploring various options, you can figure out the best way to respond and keep your business on track, no matter what happens.

Steps to Implement Automated Real-Time Network Design

Implementing automated real-time network design is crucial because it saves you from repeatedly correcting issues and ensures that your supply chain operates efficiently and effectively.

Create a Current Network Model

To begin implementing automated real-time network design, start by creating a detailed model of your current supply chain. This involves conducting an infrastructure audit to capture all existing processes, locations of warehouses, suppliers, and transportation routes.

Replicate this network in your chosen software to build a foundational model that reflects your existing operations. This model will serve as the baseline for future improvements and adjustments.

Assess Technology Readiness

Before diving into automation, it’s crucial to define your objectives and establish Key Performance Indicators (KPIs) that align with your business goals. Clear objectives and well-defined KPIs will guide your implementation process and help measure the success of your automated network design.

Ensure that your technology infrastructure is ready to support these advancements by assessing current capabilities and identifying any necessary upgrades.

Build a Data-Driven Framework

A robust data-driven framework is essential for automated network design. Develop a data integration strategy to ensure seamless flow and consistency of information.

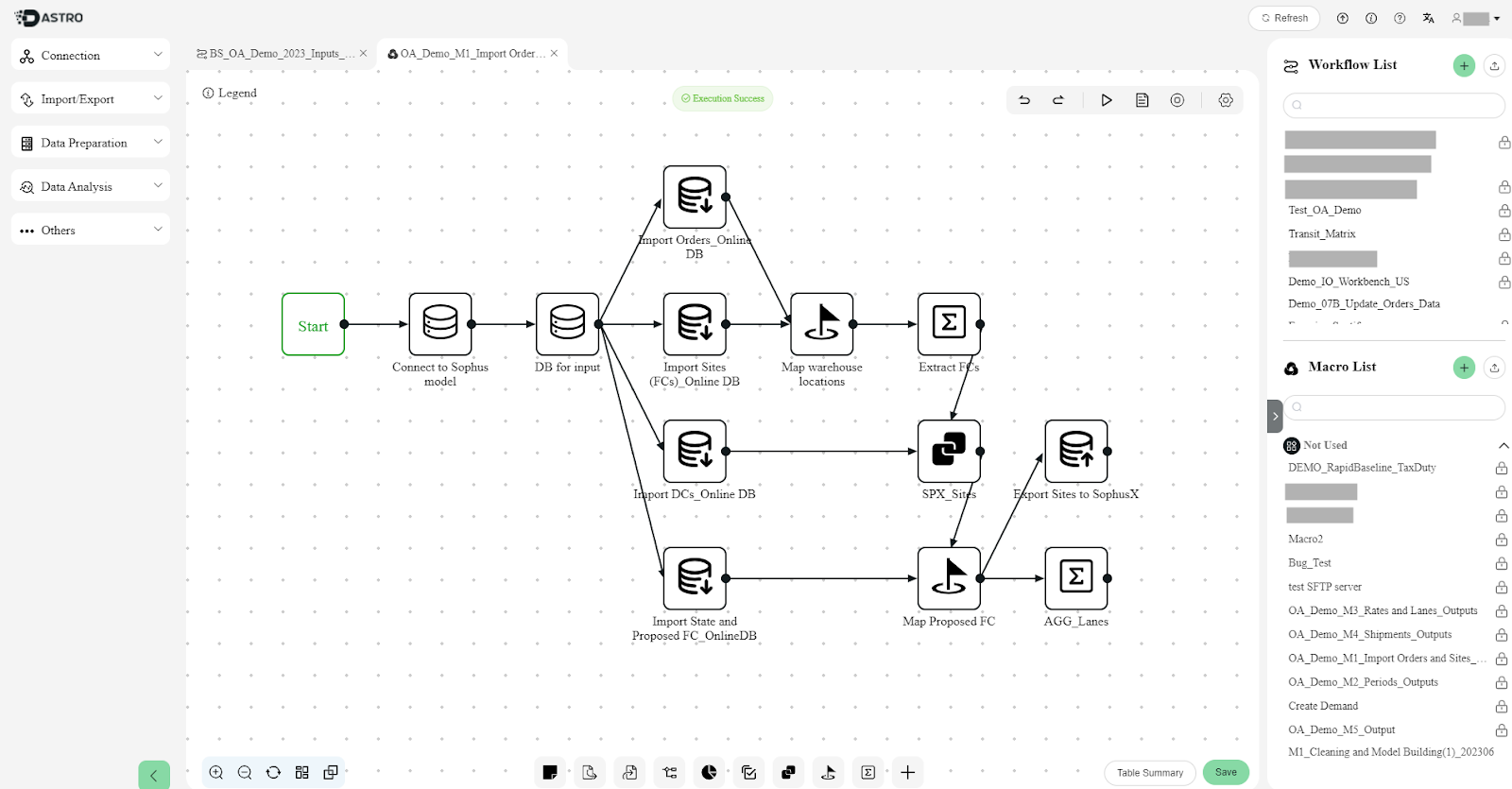

Tools like Dastro can play a critical role here, as they enable the automation of data workflows. Dastro can create auto-refreshing pipelines that integrate data into the Sophus X model, ensuring your network design remains up-to-date with the latest information.

It’s important to maintain high standards of data accuracy and consistency throughout this process.

Read about our latest Update: Exciting Update: Dastro Version 2.0 – Sophus Technology Inc

Develop and Deploy Analytics Models

With your data framework in place, focus on developing and deploying analytics models. Work with supply chain modelers to build and configure these models, allowing for both pre-defined scenarios and real-time adjustments as needed.

Select and train your models to handle specific supply chain challenges, and continuously refine them based on performance metrics and evolving business needs.

Create BI, Dashboards, and Maps

Effective visualization tools are key to understanding and utilizing your network design. Develop business intelligence (BI) tools, dashboards, and maps that can display and compare results from different scenarios.

This will help you visually interpret the impact of various changes and recommendations, facilitating more informed decision-making.

Implement Real-Time Monitoring and Alerts

To ensure your supply chain remains responsive and efficient, set up real-time monitoring systems. These systems will track performance metrics continuously and provide alerts for any issues that arise.

Establish response protocols to address these alerts promptly, helping to prevent disruptions and maintain operational smoothness.

Conduct Scenario Planning and Testing

Finally, integrate scenario planning and testing into your network design process. Design and simulate different scenarios to evaluate how various changes or disruptions might affect your supply chain.

Run these simulations to analyze potential impacts and make data-driven decisions to manage risks and use opportunities effectively.

Final Words

As you see, automating your supply chain network design is a game-changer for efficiency and agility. It helps you avoid common issues and make real-time, informed decisions with ease.

Don’t miss out on the benefits of this technology.

Reach out to us to see how Dastro can seamlessly integrate with your systems, keeping your supply chain optimized and up-to-date. Let’s make automation work for you!