Transportation costs are rising, and delivery networks are more complex than ever. Gartner reports that 76% of these initiatives fail to meet key performance metrics, often due to poor optimization, outdated systems, and a lack of agility. Traditional multi-stop routing still relies on static plans and limited visibility, which leads to higher fuel costs, empty miles, and delayed deliveries.

As logistics become more complex, old routing methods slow businesses down.

In 2026, companies need to move toward smart, data-driven transportation optimization that uses AI and real-time insights to cut costs and boost efficiency.

In this article, we’ll explore how Sophus helps businesses optimize their transportation networks with confidence.

From Multi‑Stop Routing to Networked Transportation Optimization

Traditional multi-stop routing was built for a simpler time; when demand was predictable, fuel prices were stable, and delivery schedules didn’t change by the hour. But in today’s logistics environment, these systems can’t keep pace with constant shifts in demand, traffic, and capacity. The limitations of traditional routing models make it difficult for businesses to operate efficiently at scale.

Siloed Decision Making

Most multi-stop routing frameworks still operate within functional silos. Fleet size, mode mix, distribution center alignment, and shipment frequencies are often set long before routing begins. In practice, these parameters change constantly, and traditional systems struggle to adjust.

This creates inefficiencies from the start. Companies end up with the wrong fleet composition, mismatched delivery frequencies, and poor DC-to-customer alignment. The lack of adaptability locks in waste and reduces competitiveness.

Isolated Trips and Fragmented Visibility

Conventional routing treats each trip as a separate activity instead of part of a connected network. Without coordination across routes and vehicles, opportunities for consolidation, backhauls, or shared loads are lost.

Trucks often run half-empty, fuel costs rise, and emissions increase. The network operates as disconnected journeys instead of a coordinated system, which limits overall efficiency.

Heuristic Scheduling in a Dynamic World

Many transportation plans still rely on heuristic or rule-based scheduling. These decisions often depend on personal experience or static logic. While this approach worked in simpler times, it breaks down when dealing with large, complex, and fast-changing logistics networks.

When thousands of orders, routes, and constraints must be managed in real time, manual guesswork cannot compete with data-driven optimization.

Moving Toward Networked Transportation Optimization

Forward-looking supply chain leaders are moving from route-based thinking and siloed decision-making to network-based transportation optimization. Instead of planning each trip separately, instead of a pre-set of conditions for the route’s planning, advanced models and digital twins evaluate the network and adapt to change and optimize from a holistic/connected perspective.

This connected approach integrates demand signals, network configuration, fleet capacity, warehouse operations, and carrier availability into one intelligent framework for the transportation routes optimization.

The result is more than better routing. It is networked transportation optimization, a dynamic, data-driven capability that helps enterprises truly bring down cost, minimize waste, and respond to market changes with speed and precision.

5 Ways to Effectively Optimize Transportation in 2026

Transportation optimization is about designing a connected system that links supply chain networks, transportation, warehousing, and planning into one synchronized workflow. Here are five ways businesses can build that level of efficiency in 2026:

1. Aligning Transportation with Supply Chain Network Design

Transportation efficiency starts with how the overall network is structured. Routes perform best when they are aligned with the right warehouse locations, fleet size, mode mix, and shipping frequencies. A well-designed supply chain network reduces unnecessary mileage and shortens lead times.

Software like test.sophus.ai/ helps model and optimize supply chain layouts, ensuring that transportation routes directly support cost efficiency and service reliability.

2. Route Planning Based on Demand Clusters

Planning routes around demand clusters makes transportation smoother and more efficient. When orders going to nearby areas are grouped, it reduces travel time, fuel use, and delivery costs.

With better/more accurate demand forecasting, companies can plan routes and transportation resources that meet real customer needs, helping avoid backorders and lost sales, and overcapacity of the assets. This keeps fleets productive and utilization maximized, and customer service is still met.

3. Using AI for End-to-End Optimization

AI connects all parts of logistics, from production to inventory and demand forecasting to last-mile delivery. It uses predictive insights to forecast order volumes, identify peak demand periods, and plan resources accordingly.

Companies should analyze vehicle capacity, traffic, and delivery windows to create transport schedules and resource plans that better meet the needs of the potentially volatile demand and external factors. This can reduce empty miles, prevent delivery delays, and ensure better use of fleet and warehouse capacity.

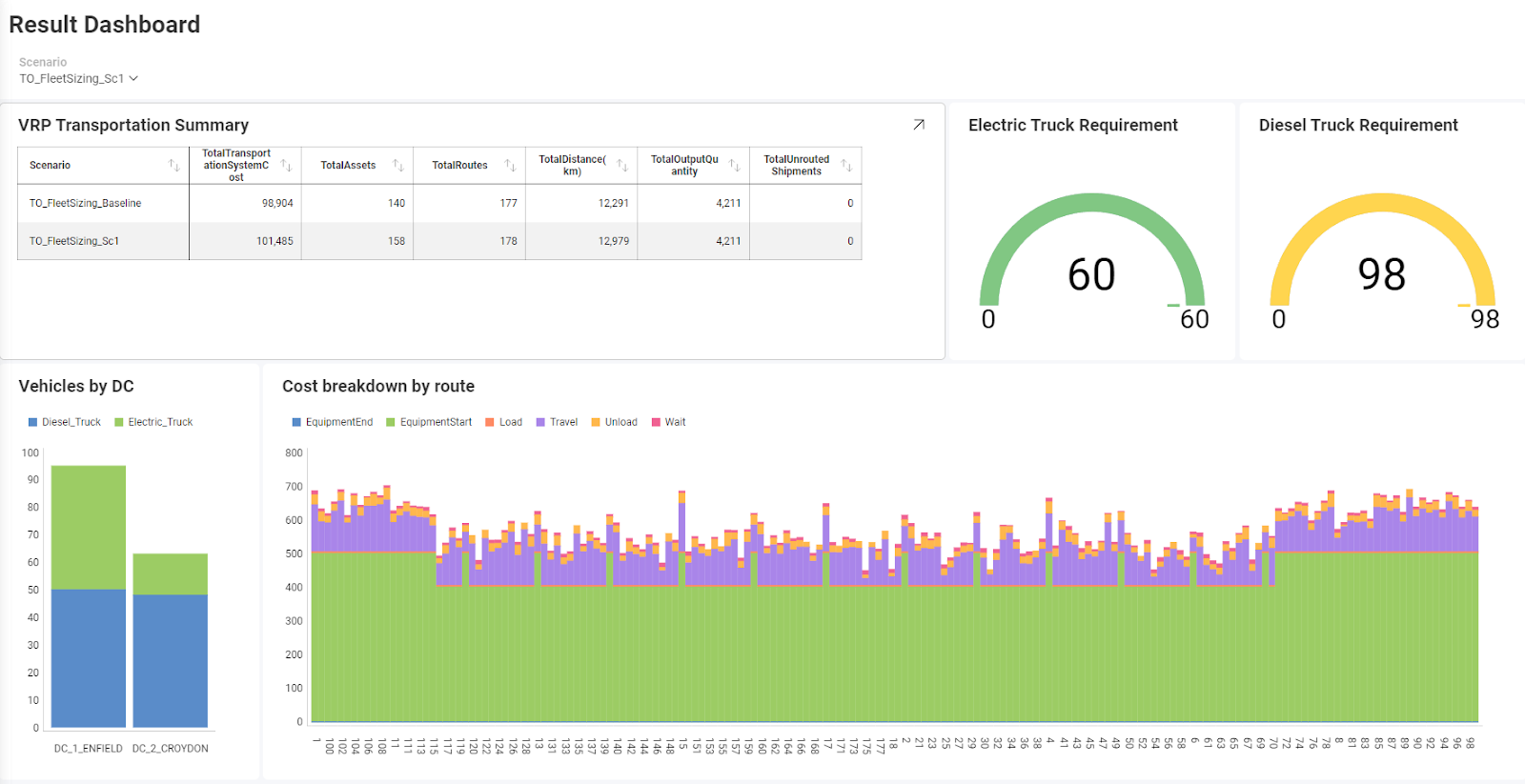

4. Scenario Planning

With supply chain scenario planning, businesses can test different situations such as fuel price hikes, delivery delays, or capacity limits to prepare for change before it happens.

Sophus supports this by allowing users to simulate multiple transportation scenarios, compare outcomes, and choose the most efficient and resilient route strategies.

5. Integrating Transportation into Supply Chain Strategy

Transportation shouldn’t operate in isolation. It’s an integral part of the overall supply chain strategy, influencing cost, speed, and sustainability outcomes. Network design platforms like test.sophus.ai/ bring all these decisions together, helping businesses evaluate trade-offs between modes, locations, and capacities.

The result is a unified, efficient system that supports growth and adaptability across the supply chain.

How Sophus X helps in Transportation Optimization?

Transportation Optimization

Sophus X makes transportation routing smarter, cheaper, and more efficient by using advanced data and AI-driven decisions.

-

Optimizes multi-stop routes to reduce fuel and distance while meeting delivery constraints.

-

Considers real factors like vehicle type, capacity, range, service time, and cost.

-

Cuts transportation costs by improving vehicle utilization and reducing empty miles.

-

Ensures on-time deliveries by planning routes that meet delivery time windows.

-

Maximizes vehicle capacity so fewer trips are needed, saving fuel and time.

-

Uses real road distance and time data for accurate planning and reliable ETAs.

-

Avoids restricted zones based on vehicle rules and compliance limitations.

-

Reduces GHG Emission modeling with fuel-efficient routing and fewer unnecessary miles.

Conclusion

Transportation optimization today is less about choosing the shortest route and more about creating a system that adapts and performs well in constantly changing conditions. Companies that connect their data, automate decisions, and plan across the full network see fewer disruptions and more reliable deliveries.

As 2026 approaches, success will depend on how well businesses can predict and respond to new challenges. Sophus Technology helps logistics teams do exactly that by simulating real-world scenarios and optimizing routes that balance cost, speed, and service performance.

Want to see how this works in your own network? Schedule a demo with Sophus and discover how smarter optimization can turn your transportation challenges into opportunities.

FAQs

1. What is transportation optimization?

Transportation optimization is the process of planning and managing routes, loads, and modes of transport to reduce costs, improve delivery times, and increase overall efficiency. It focuses on using data and technology to make smarter logistics decisions across the entire network.

2. What is the transportation model used in supply chain optimization?

The transportation model is a mathematical framework that helps allocate shipments between sources and destinations at the lowest possible cost while meeting demand and capacity constraints. It’s widely used to balance efficiency and service quality in logistics planning.

3. What are the three types of supply chain optimization models?

The three main types are strategic, tactical, and operational models. Strategic models focus on long-term decisions like facility locations, tactical models manage planning and capacity, and operational models handle daily activities such as routing and scheduling.

4. Which optimization technique is best?

The best technique depends on the problem. Common methods include linear programming, heuristic algorithms, and AI-driven predictive modeling. Today, many companies use a mix of these techniques for faster, more accurate decision-making.

5. What is the first step of supply chain optimization?

The first step is to map and understand your current network. This includes identifying demand patterns, transportation flows, and cost drivers. Once the data is clear, tools like Sophus can help simulate different scenarios to find the most efficient network design.